| |

|

|

|

| |

| Commercial Kitchen Planning Kitchen

Piping |

| |

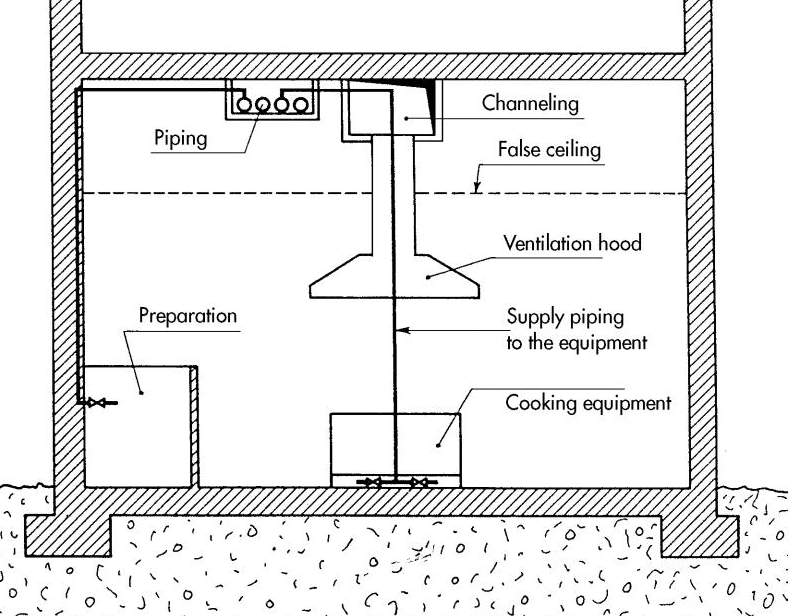

The optimal position for supply piping is to use dorsal

piping attached by brackets to the top of a specific supply

conduit located beneath the kitchen (ideal for assembly,

inspection and maintenance).

|

| |

The piping leading

to wall mounted exit points must all go into chasing (conduits)

(except that for gas, which by law must always be in view).

Floor piping must be in special conduits in order to avoid

affecting the water-

proofing.

However, the structure of the building does not always

allow for this opti mal solution to be carried out and alternative

solutions have to be found.

The supply pipes in these cases can be placed in the ceiling,

separated from the kitchen by a false ceiling or in the

ceiling of the floor beneath the kitchen (generally in storerooms,

dispensers etc.) in view or with a false ceiling. They can

even be in the floor of the kitchen itself in a practical

trough which is aired and drained and from which the piping

to each 24 piece of equipment will extend in chasing.

Every appliance needing to be supplied with hot or cold

water, steam, or gas must be attached to the supply network

by means of conical joints pre ceded by a spherical valve

so that the supply can be cut off and a par ticular piece

of equipment disconnected from the system (for maintenance)

without having to stop other appliances functioning.

As already stated, it is not advisable to place the supply

network on view (above the plaster or the tiles) as this

would readily lend itself to becoming a dirt trap that is

difficult to clean. Only the gas system by law should be

on view for obvious reasons, however it’s piping is

painted and not insu lated. |

|

Cold and hot water - The optimum hardness of water is between

5° and 7°F. The temperature of hot water can be between

48° and 60°C.

For the network, it is advisable to use normal galvanized

steel (UNI 3824) with special threaded galvanized joints and

connections. For the immedi ate use of hot water, the supply

network should have a re-circulation sys tem. |

Steam-condensation - Special equipment should

be adequately sup plied with the specific pressure required,

every appliance should have an appropriate steam condenser.

For the supply network it is normally advis able to use black

welded pipes, or black pipes of the type UNI 3824, with their

relative threaded joints and connections.

|

Gas - Equipment needing to be supplied by gas

has to adhere to current regulations. There are three types

of gas commercially available:

The systems used for the supply of gas have to comply to the

current regu lations for that type of gas. |

| |

| The supply network for cooking appliances and

dishwashers can be installed in an area below, adjacent or

in communication with those des

tined to the consumption of meals and/or the location of people

depen

dent on the following conditions:

1.The communicating door must be smoke resistant with

an automatic or

otherwise device to close the door properly in the event

of fire and an

appropriate smoke detector. 25

2. The area to contain the above system has to be provided

with one or

more ventilation zones with a surface of not less than 1/20th

of the area

of the kitchen with a minimum of 0.5 m .

3.The installation of cooking and dishwashing areas where

meals are to

be eaten is allowed provided that the whole area is constructed

bearing

in mind the previous two points.

4. Each burner must have a flame failure device with a

maximum gas cut

off time of 60 seconds if the flame is accidentally extinguished.

a) Fireproof and smoke proof poor automatically closed

by a smoke detector.

b) Smoke detector.

c) Fire proof and smoke proof door automatically closed

by a smoke detector.

d) Ventilation area.

e) Ventilation area.

f) Burners with flame failure devices.

g) Gas meter. |

| |

| |

| |

| Back

to Hvac App. Commercial Kitchen Main Page |

| Back to Hvac

Expert Main Page |

|

|

|

|

|

|

|