| |

|

|

|

| PROCESS PIPING |

|

| |

|

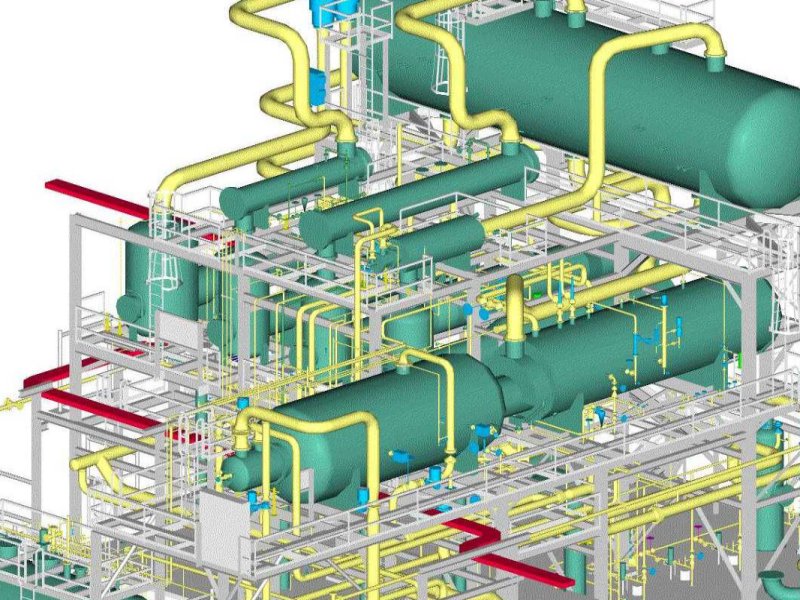

What is process piping system

Piping system: conveys fluid between locations .These can

be any fluid .(air,water ,milk,solvents)

Piping system includes:

•Pipe

• Fittings (e.g.

elbows, reducers, branch connections, etc.)

• Flanges, gaskets,

bolting

•Valves

• Pipe supports

|

|

|

|

| Types of Process Diagrams Process diagrams

can be broken down into two major categories:

process flow diagrams (PFDs) and process and instrument

drawings (P&IDs),

sometimes called piping and instrumentation drawings. A

flow diagram is a simple illustration that uses process

symbols to describe the primary flow path through a unit.

A process flow diagram provides a quick snapshot of the

operating unit. Flow diagrams include all primary equipment

and flows. A technician can use this document to trace the

primary flow of chemicals through the unit. Secondary or

minor flows are not included. Complex control loops and

instrumentation are not included. The flow diagram is used

for visitor information and new employee training.

A process and instrument drawing is more complex. The P&ID

includes a graphic representation of the equipment, piping,

and instrumentation. Modern process control can be clearly

inserted into the drawing to provide a process technician

with a complete picture of electronic and instrument systems.

Process operators can look at their process and see how

the engineering department has automated the unit. Pressure,

temperature, flow, and level control loops are all included

on the unit P&ID. |

|

|

|

| Basic Instrument Symbols Process

technicians use P&IDs to identify all of the equipment,

instruments, and piping found in their units. New technicians

use these drawings Knowing and recognizing these symbols

is important for a new technician. The chemical processing

industry has as- signed a symbol for each type of valve,

pump, compressor, steam turbine, heat exchanger, cooling

tower, basic instrumentation, reactor, distillation column,

furnace, and boiler . There are symbols to represent major

and minor process lines and pneumatic, hydraulic, or electric

lines, and there is a wide variety of electrical symbols.

Some symbols are common among plants; others differ from

plant to plant. Some standardization of process symbols

and diagrams is taking place. The symbols used in this chapter

reflect a wide variety of petrochemical and refinery operations.

Typical process symbols |

|

|

|

Flow Diagrams

New technicians are required to study a simple flow diagram

of their as signed operating system. Process flow diagrams

typically include the major equipment and piping path the

process takes through the unit. As operators learn more about

symbols and diagrams, they graduate to the much more complex

P&IDs. |

|

| |

|

Equipment Location Drawing

Equipment location drawings (plot plans) show the exact location

of equipment in relation to the plant’s physical boundaries.

One of the most difficult concepts to explain to a new process

technician is the scope and size of modern chemical processing.

Most chemical plants and refineries closely resemble small

cities; they have well-defined blocks and areas connected

by a highway of piping and equipment. Equipment location drawings

provide information about the neighborhood.

|

|

| |

|

| Loop Diagrams A loop diagram traces

all instrument connections between the field instrument

and the control room panel. This includes instrument air

lines, wiring

connections at field junction boxes, and control room panels

and front connections

connections.

• Process

Piping Software |

|

|

|

|

|

|

|

|