| |

|

|

|

| Kitchen Exhaust And Makeup Systems Design Procedure

|

| |

The Design Process

Successfully applying the fundamentals of commercial

kitchen ventila-

tion (CKV) during the design process requires a good

understanding of the loca

building code requirements, the menu and appliance preferences,

and the pro-

ject’s budget. Information about the kitchen equipment

and ventilation re-

quirements may evolve over the course of the design

phase. Data needed by

other members of the design team may require early estimates

of certain pa-

rameters (e.g., the amount of exhaust and makeup air,

motor horsepower, water

supply and wastewater flow rates). As more decisions

are made, new informa-

tion may allow (or require) refinements to the design

that affect exhaust and

makeup air requirements.

The fundamental steps in the design of a CKV system

are:

1. Establish location and “duty” classifications

of appliances including

menu effects. Determine (or coordinate with foodservice

consult-

ant) preferred appliance layout for optimum exhaust

ventilation.

2. Select hood type, style, and features.

3. Size exhaust airflow rate.

4. Select makeup air strategy; size airflow and layout

diffusers.

Steps 1 through 3 are discussed in this Design Guide;

Step 4 is the subject of

Design Guide 2, Improving Commercial Kitchen Ventilation

Performance – Optimizing

Makeup Air.

A good understanding of how building code requirements

apply to

kitchen design is essential. Local or state building

codes are usually based on

one of the “model” building codes promulgated

by national code organizations

(see sidebar). Our discussion of the building codes

will be limited to require-

ments that affect design exhaust and makeup air rates,

which are usually found

in the mechanical code portion of the overall building

code.

Historically, codes and test standards used “temperature”

ratings for

classifying cooking equipment. Although these temperature

ratings roughly cor-

related with the ventilation requirement of the appliances,

there were many gray

areas. During development of ASHRAE Standard 154, Ventilation

for Com-

mercial Cooking Appliances, it was recognized that plume

strength, which takes

into account plume volume and surge characteristics,

as well as plume tempera-

ture, would be a better measure for rating appliances

for application in building

codes. “Duty” ratings were created for the

majority of commercial cooking ap-

pliances under Standard 154, and these were recently

adopted by the International Mechanical Code (IMC)

|

|

|

. The Kitchen Ventilation chapter of the

ASHRAE Applications Handbook (2003 edition) applied

the same concept to

establish ranges of exhaust rates for listed hoods.

The appended Design Exam-

ples in this Guide reference duty classifications

for appliances. The duty classifi-

cations listed in the sidebar are from ASHRAE Standard

154-2003, Ventilation

for Commercial Cooking Operations.

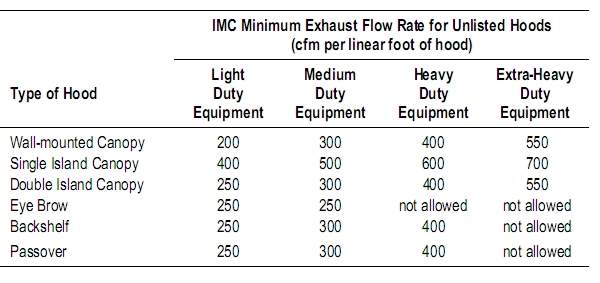

The IMC dictates exhaust rates based on hood type

and appliance duty.

Table 1 states these exhaust rates in “cfm per

linear foot of hood” (“linear foot”

in this case applies to the distance from edge to

edge along the front face of the

hood). The Code requires that the exhaust rate for

the highest duty-rated appli-

ance be applied to the entire hood. The Uniform Mechanical

Code (UMC), used

in many California jurisdictions, requires calculating

exhaust rates based on

square-footage of capture area (capture area is the

open area defined by the

lower edges of the hood). The UMC uses temperature

classifications for appli-

ances, as described above. Both the IMC and the UMC

require a minimum 6-

inch hood overhang (front and sides) for canopy style

hoods. |

| |

|

Kitchen

Exhaust And Makeup Systems Design Procedure 2 |

| Commercial

Kitchen Exhaust and Makeup Air Systems Design |

. |

| Back to Hvac Applications

Main Page |

| Back to Hvac Expert Main

Page |

|

|

|

|

|

|

|