| |

|

|

|

|

INDUSTRIAL VENTILATION DUST COLLECTION SYSTEM DESIGN

PAINT DIP -SOLVENT VAPOURS

PAINT

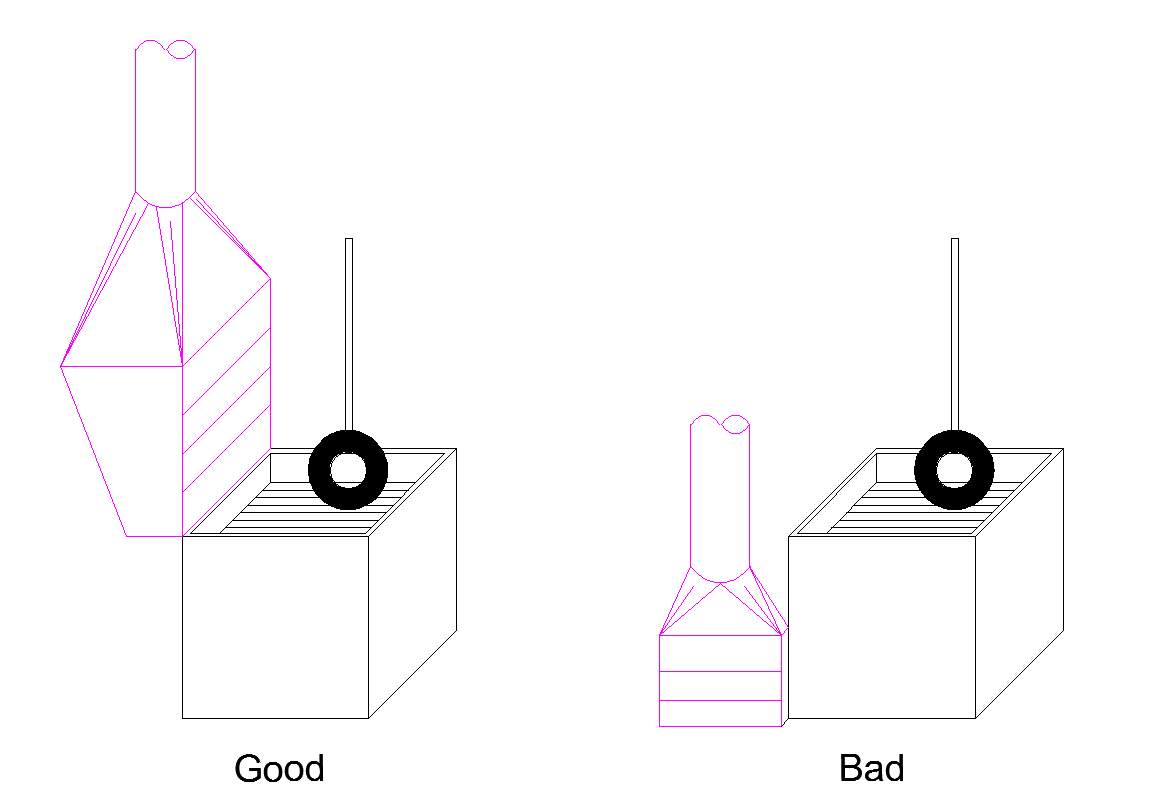

DIP -EXHAUST HOOD LOCATION |

|

| Solvent vapors in

health hazard concentrations are not always heavier than

air. |

| Exhaust from floor

only gives fire proteciton only ; |

Ex:

|

|

Denisty of

air : |

1 |

Denisty of

%100 amyl acetate vapor : |

4,49 |

Density of

lowest explosive mixture : |

1,038 |

Density of

T.L.V (*)mixture : |

1.0003 |

| |

|

* T.L.V The threshold

limit value (TLV) of a chemical substance is believed to

be a level to which a worker can be exposed day after day

for a working lifetime without adverse effects. Strictly

speaking, TLV is a reserved term of the American Conference

of Governmental Industrial Hygienists (ACGIH).

|

|

| |

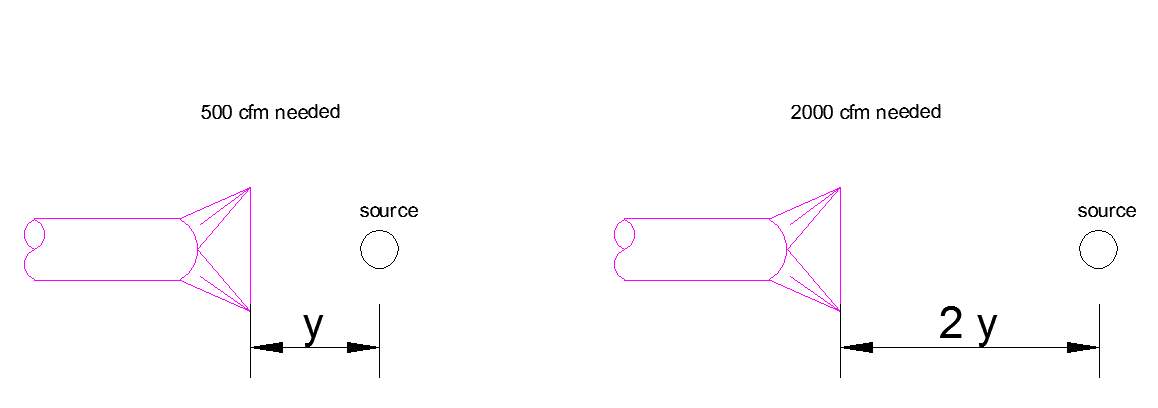

Place

hood as close as to the source.Required volume varies with

square of distance.Required exhaust air volume varies with

square of distance

|

| Where ; |

| Capture Velocity |

V |

fpm |

Air velocity at any point in

front of the hood or at the hood opening ,neccesary to capture

the contaminated air at that poinby causing it to flow into

the hood. |

| |

|

|

|

| Face Velocity |

Vf |

fpm |

Air velocity at the hood opening |

| |

|

|

|

| Slot Velocity |

Vs |

fpm |

Air velocity through the openings in a slot

type hood |

| |

|

|

|

| Plenum Velocity |

Vp |

fpm |

Air velocity in the plenum |

| |

|

|

|

| Duct Velocity |

Vd |

fpm |

Air velocity through the duct after hood. |

| |

|

|

|

| Transport Velocity |

Vt |

fpm |

Minumum air velocity through the duct required

to move particules in air stream. |

| |

|

|

|

| Dust Distance |

X |

ft |

Distance outward along center axes of hood. |

| |

|

|

|

| Air Flow |

Q |

cfm |

Required minumum air flow to capture dust

particles |

| |

|

|

|

| Area |

A |

ft2 |

Area of hood opening |

| |

|

|

|

| Diameter |

D |

ft |

Diameter of round hoods |

Dust Exhaust

system Hood Entry Losses Table

Back

|

|

|

|

|

|

|