|

INDUSTRIAL VENTILATION DUST COLLECTION SYSTEM DESIGN

Range of Capture Velocities in Hood

Design

Proper design of exhaust hoods is a must If you want effectively

control athmospheric contanimation at its source with minumum

air flow and power consumption.The theory of capture velocity

depends on the creation of air flow past the source of contaminant

sufficent to remove highly contaminated air around the source

and to draw air into an exhaust hood.

Dust particles in micron sizes ,even if throwed high velocities

travel very short distance and after a few inches follow the iar

currents.The same for mist ,fumes ,vapors and gases.

Larger dust particles relased at high velocities have a trajectory

in air.Unless they are directed to hood ,they cannot be captured..

| Condition

of Contaminant |

Examples |

Capture Velocity |

| |

|

V |

| Released with practically

no velocities into quiet air |

Evaporation from tanks ,cooking

etc |

50-100 fpm |

| 0,25-0,50 m/sn |

| |

|

|

| |

|

|

| Released at low velocity

into moderatly still air |

Spary booths,intermittent container

filling ,low speed container transfers ,welding,plating |

100-200 fpm |

| 0,5-1 m/sn |

| |

|

|

| |

|

|

| Acitve generation

into zone of rapid air motion |

Spray painting in shallow booths

,barrel filling ,conveyor loading,crushers |

200-500 fpm |

| 1-2,5 m/sn |

| |

|

|

| |

|

|

| Released at high

initial velocity into zone of very rapid air motion |

Grinding,abrasive blasting,tumbling |

500-2000 fpm |

| 2,5-10 m/sn |

| |

|

|

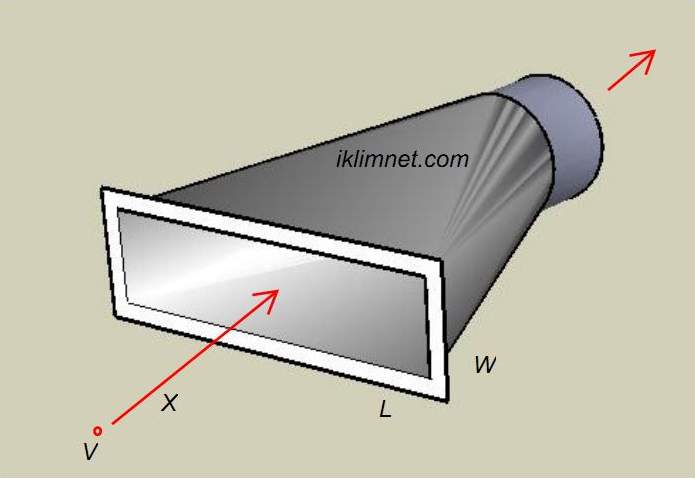

Dust Exhaust

System Hood Types

Dust Explosions

A dust explosion is very similar to a gas or vapour cloud explosion,

i.e. when a volume of a flammable mixture is ignited, resulting

in a rapid pressure increase and fire moving through the cloud.

A dust explosion occurs when a combustible material is dispersed

in the air forming a flammable cloud and a flame propagates through

it. This of course also depends on the supply of oxygen to the

fire, and the concentration of the fuel, if either of these are

in too high or low then the explosion will not occur.

|